All about Electrical Grounding Systems!

The ground is the common point of return for an electrical flow. The grounding system is a backup pathway that has an alternate route for an electrical current to flow to ground due to any risk in the electrical system before it gets a fire or shock.

Simply, “grounding” means a low-resistance path has been made for electricity to flow into the ground. A “grounded” connection includes a connection between the electrical equipment and a ground through a wire. Once wired properly, this provides your devices and appliances a secure place to discharge excess electrical current. This will potentially prevent electrical equipment from several risks. The ground wire in an electric outlet is basically a safety valve.

Need of Grounded system in an electrical Network:

Particularly in large-scale residential or commercial projects, some people think that it will be difficult and time consuming to install a grounding system and any additional construction of electrical material, if timely maintenance is performed. This is an extremely dangerous practice that could lead to a shock if the internal wiring in the appliance become short circuit.

There are several common risks involved in an ungrounded electrical system for both the personnel and equipment.

Types of Grounded System:

Three different types of grounding system are used to provide protection in an electrical system.

Common Methods for Electrical Grounding Systems:

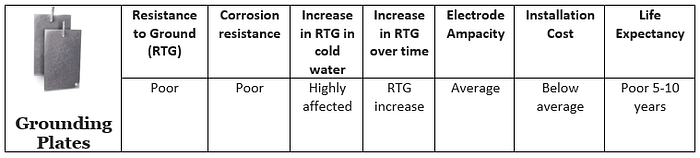

Grounding Plates

Grounding plates are made up of copper or Galvanized Iron (GI) and placed vertically into the ground in a pit (filled with charcoal and salt layers) over 10 feet deep. For a higher electrical grounding system, the earth moisture condition must be maintained around the grounding plate system.

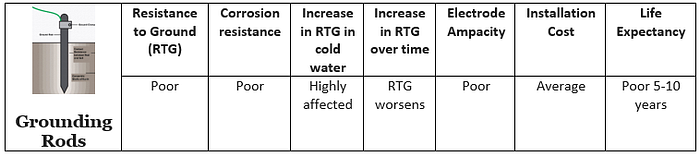

Grounding Pipes and Rods:

A galvanized steel pipe (mixture of salt and charcoal) is placed vertically into the soil through drilling for connecting the grounding wires. The length and diameter of the pipe size mainly depends on the type of soil and electrical installation (magnitude of current). The soil moisture will decide the pipe’s length to be placed in the ground.

Stay Sharp & Join our Mailing List!

Our surveys show that 90% of the people who join our blog have found the content valuable! Join today

Importance of Grounding Electrical Currents:

People often wonder why electrical grounding is important even after installing quality equipment and performing periodic maintenance. Here are a few benefits of getting your system grounded for both residential and commercial facilities.

Conclusion

Electrical grounding system ensures personal and equipment safety while working on the line. Remember, a line that’s de-energized will simply become energized in the blink of an eye, therefore electrical system should be kept safely grounded in all times.

Let us know if you have any queries regarding this topic and do provide us with your feedback in the comments.

About The Author

Abdur Rehman is a professional electrical engineer with more than eight years of experience working with equipment from 208V to 115kV in both the Utility and Industrial & Commercial space. He has a particular focus on Power Systems Protection & Engineering Studies.

Abdur Rehman is the CEO and co-founder of allumiax.com and creator of GeneralPAC by AllumiaX. He has been actively involved in various roles in the IEEE Seattle Section, IEEE PES Seattle, IEEE Region 6, and IEEE MGA.